- Overview

- Inquiry

- Related Products

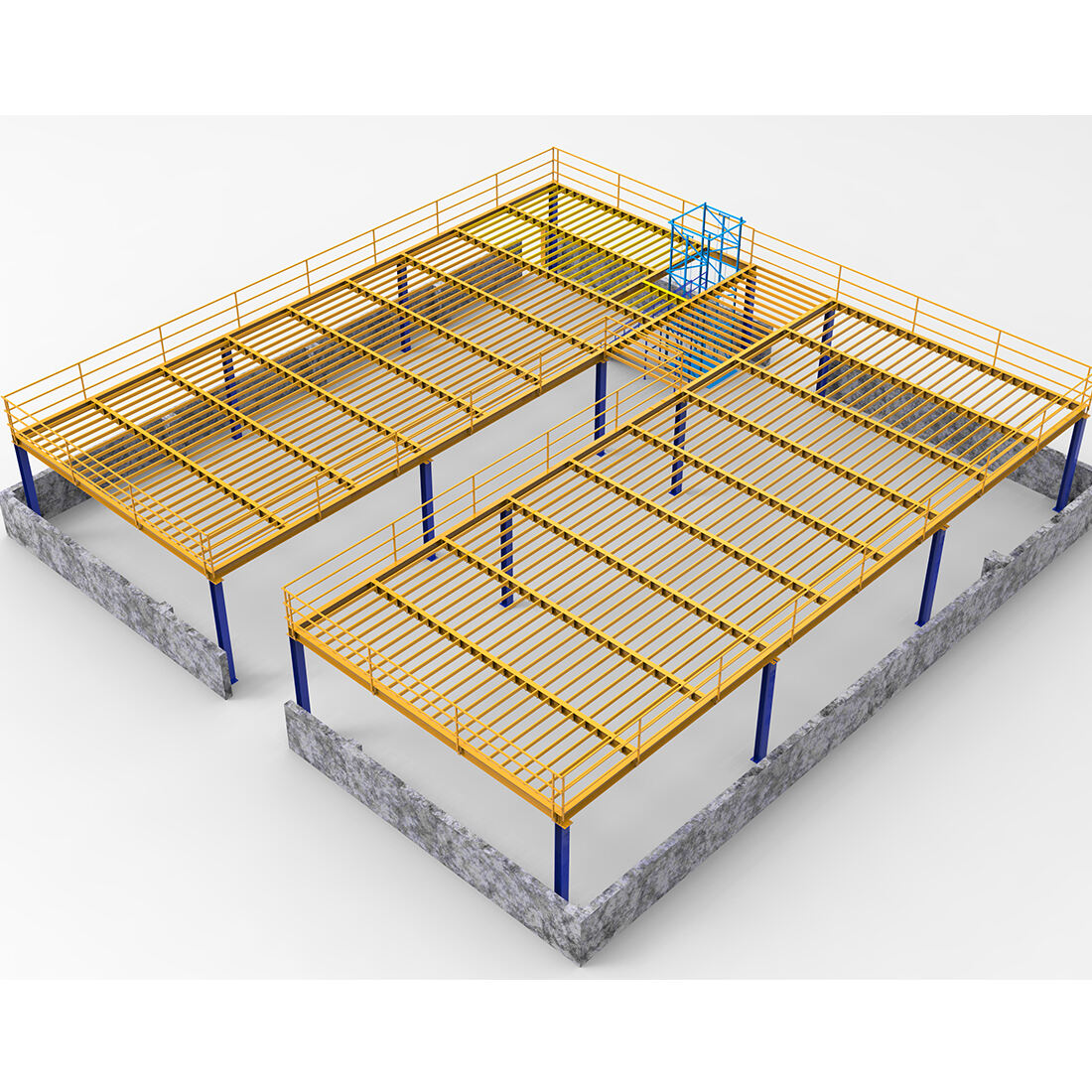

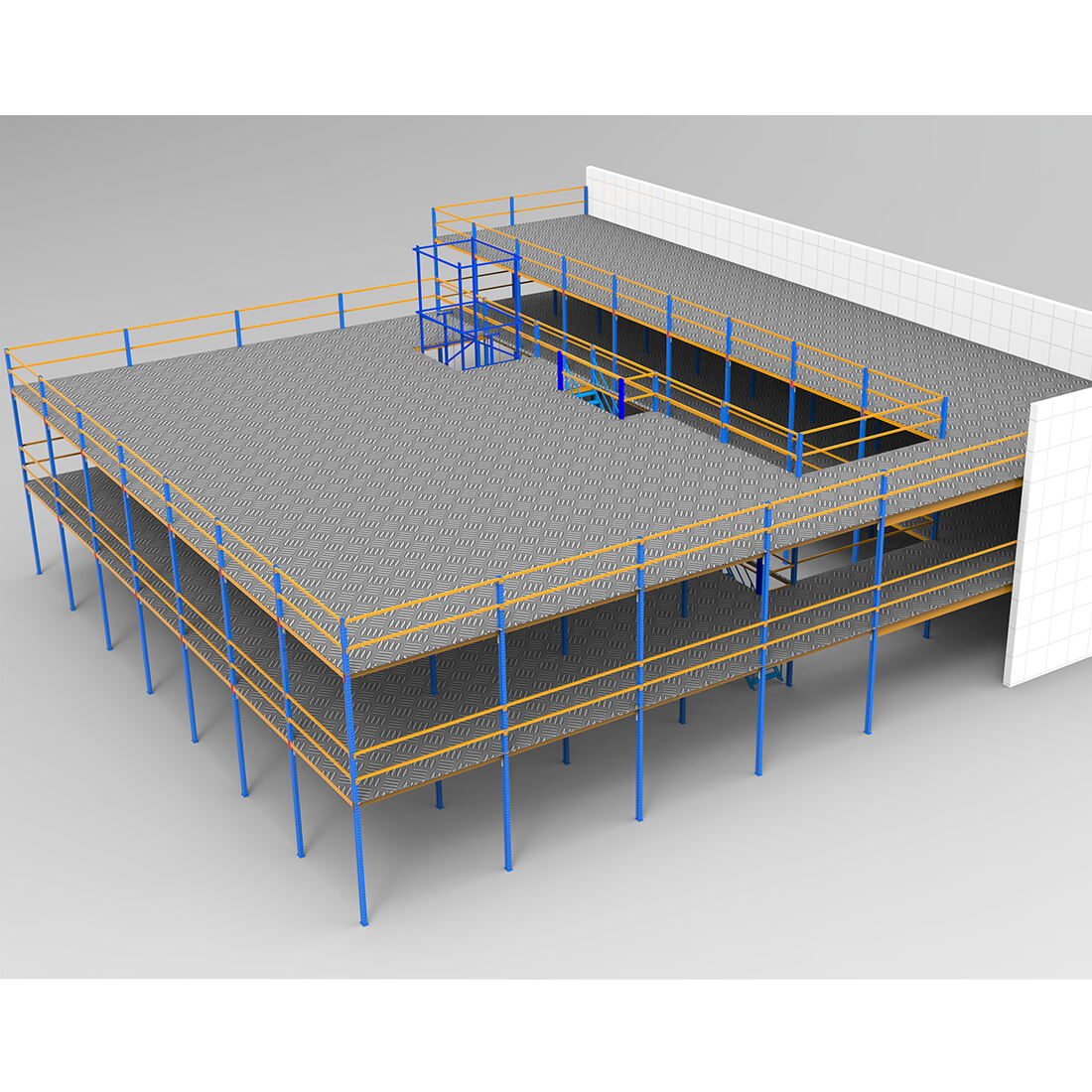

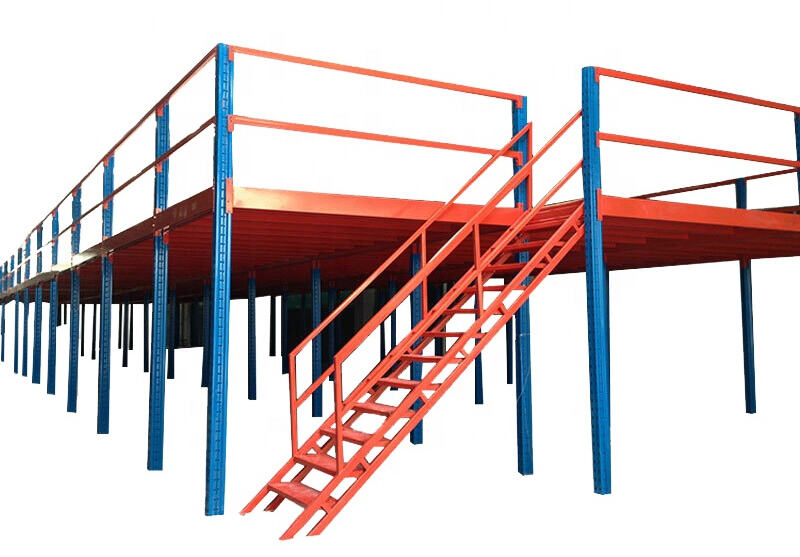

Core Structure and Design Features:

A mezzanine shelf mainly consists of three parts: a load-bearing frame, floor panels, and auxiliary facilities. Its structural design focuses on stability and practicality.

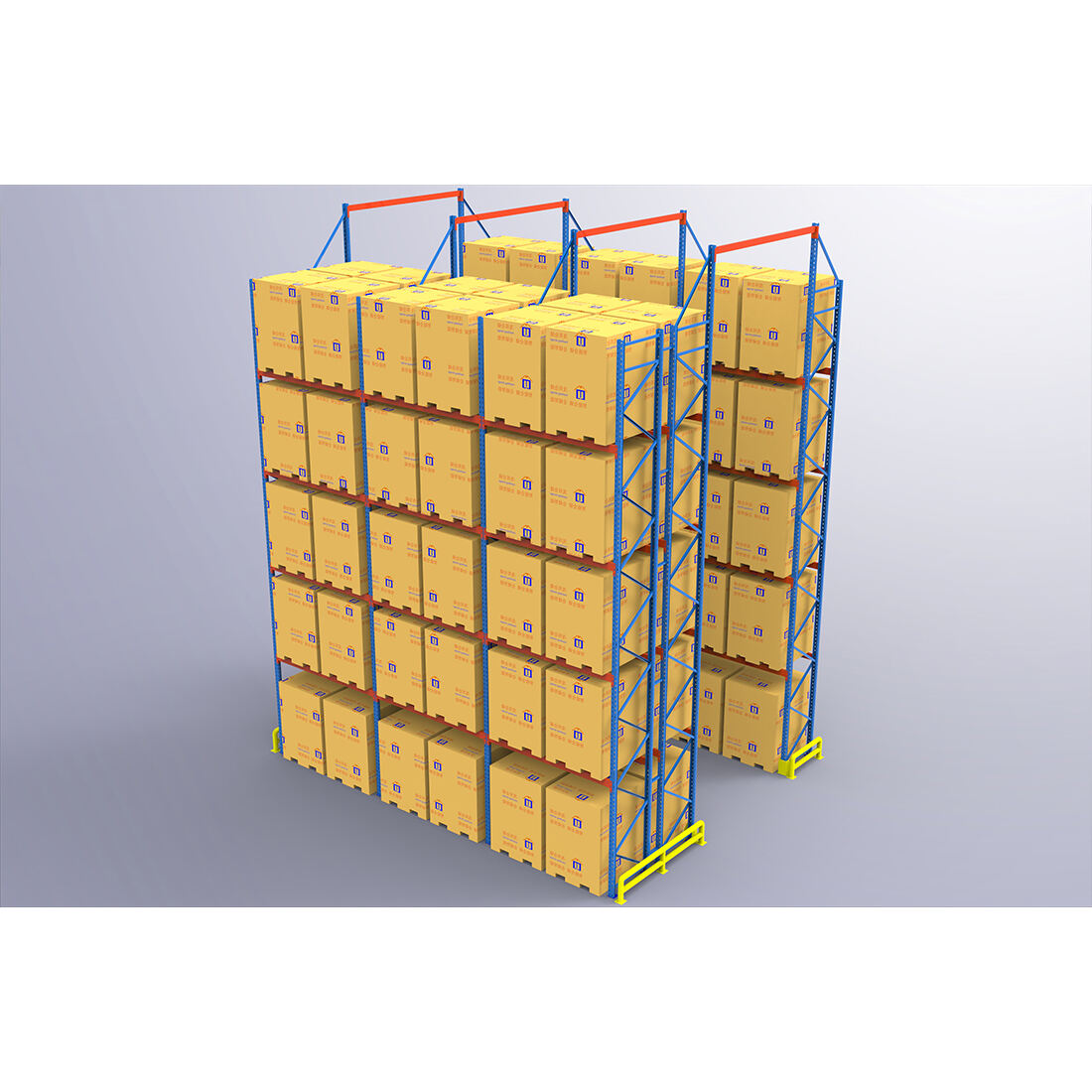

Load-bearing Frame:It uses high-quality steel as columns and main beams, which are assembled via bolted connections to form a stable supporting framework. The load-bearing capacity of the frame is designed per floor, with a typical single-floor load-bearing capacity ranging from 300 to 800 kg/㎡. Reinforced versions can be customized according to the weight of the goods.

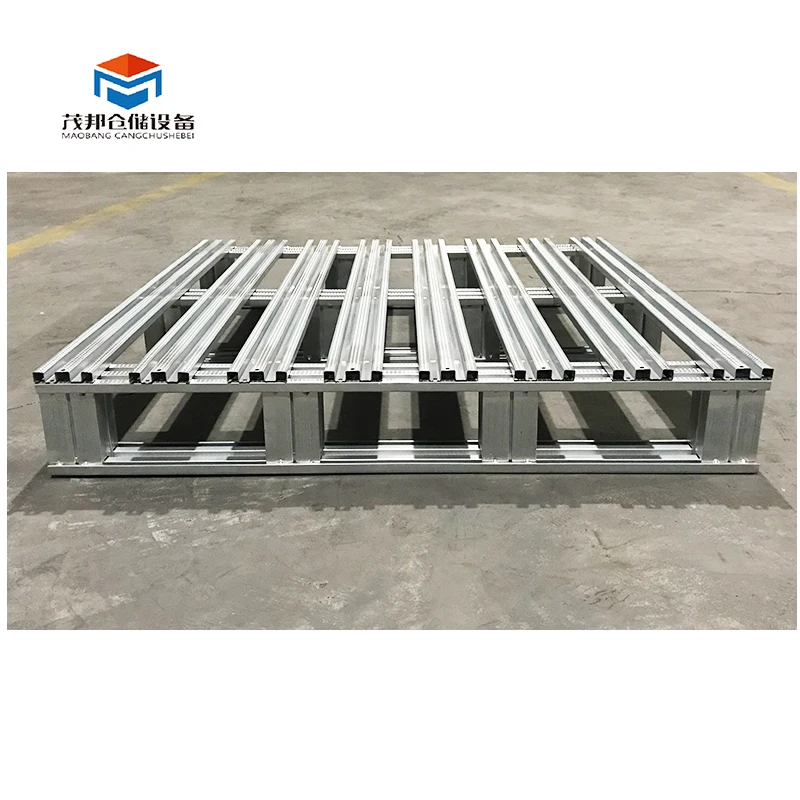

Floor Panels:Different materials are selected based on storage needs, with common types including:

---Steel (Steel Decking): High load-bearing capacity and wear resistance, suitable for placing heavy cartons or small pallets of goods.

---Grid Panels: Good air permeability and light weight, facilitating observation of goods on the lower floor, suitable for storing light small items.

---Wooden Panels: Lower cost, suitable for storing light industrial products without oil stains or sharp edges.

Auxiliary Facilities:Standard configurations include stairs (or hydraulic freight elevators) for personnel to go up and down. Some are equipped with guardrails and anti-slip strips to ensure safety, and conveyor interfaces can also be reserved to realize automated transfer of goods between upper and lower floors.

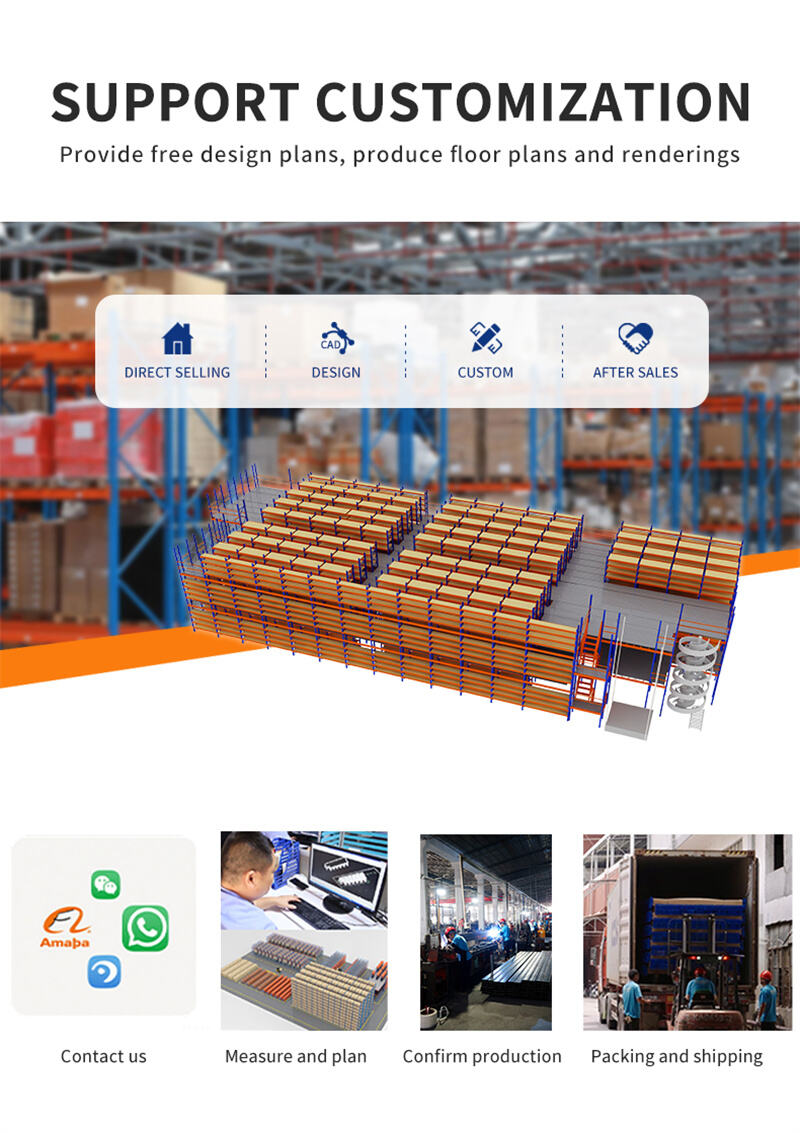

If you know the specific height of your warehouse and the type of goods to be mainly stored (such as split-picked small items or lightweight boxed goods), I can help you design a mezzanine shelf layout sketch, marking key information such as floor height, aisle width, and storage area division, to provide a reference for subsequent communication with suppliers.

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

TH

TH

MS

MS

HMN

HMN

KM

KM

LO

LO

MR

MR

TA

TA

MY

MY

SD

SD