- Overview

- Inquiry

- Related Products

Structural Composition

Upright Frames: Comprised of two vertical columns, cross braces, and diagonal braces, these are connected using nylon self-locking bolts. The vertical columns feature double rows of diamond-shaped holes with a pitch of either 75mm or 50mm, enabling beams to be hung and adjusted freely along their height. The cross-section of the columns is made up of multiple surfaces, offering a significant moment of inertia and robust impact resistance.

Beams: Each beam is formed by welding two column clips to a beam rod. The beams are made by welding two specially designed channel-shaped beams, which thicken the upper and lower surfaces of the beam, resulting in light weight, strong load-bearing capacity, and low cost. When connecting beams to upright columns, safety pins with lugs are equipped to prevent beams from falling off after being hit by external forces.

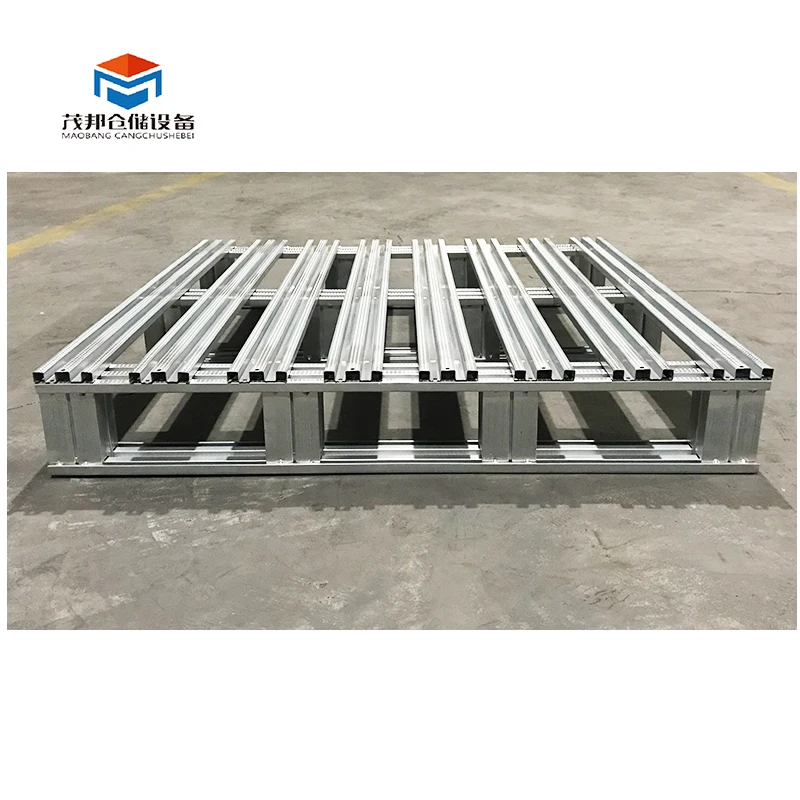

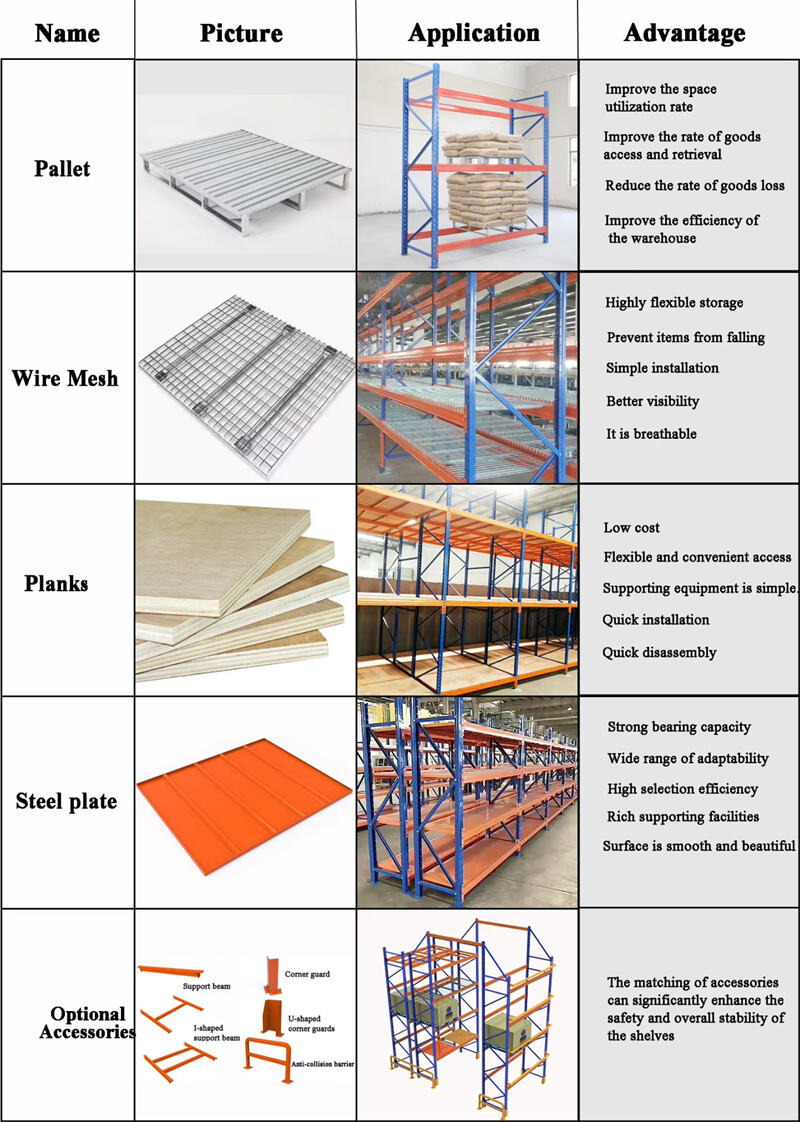

Shelves (Optional): Shelves made of materials such as steel plates, melamine boards, or grid meshes can be configured according to needs. This allows for the use of pallets of different sizes or the storage of bulk goods and small items.

Key Features

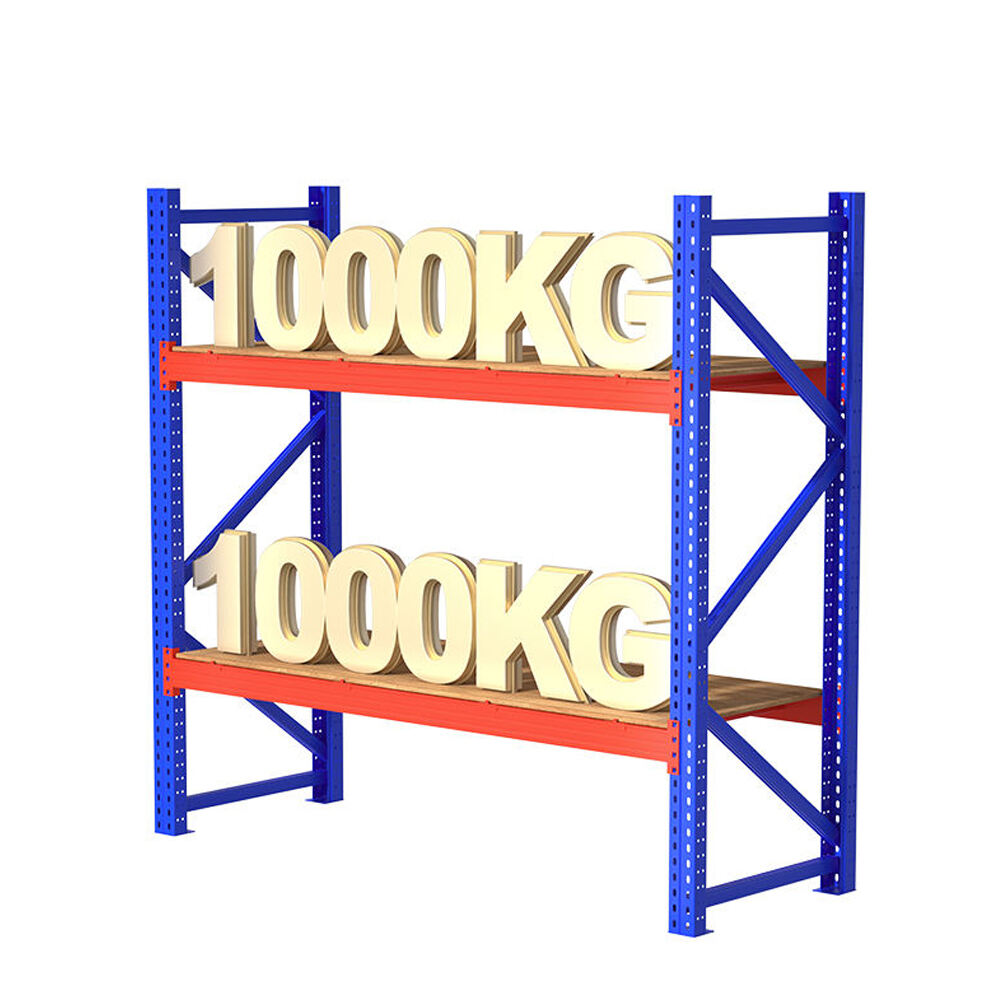

Strong Load-Bearing Capacity: Constructed from high-quality cold-rolled steel, the single-layer load-bearing capacity can exceed 500KG. Certain models boast a maximum single-layer load capacity of up to 5000KG, making them ideal for storing heavy palletized goods.

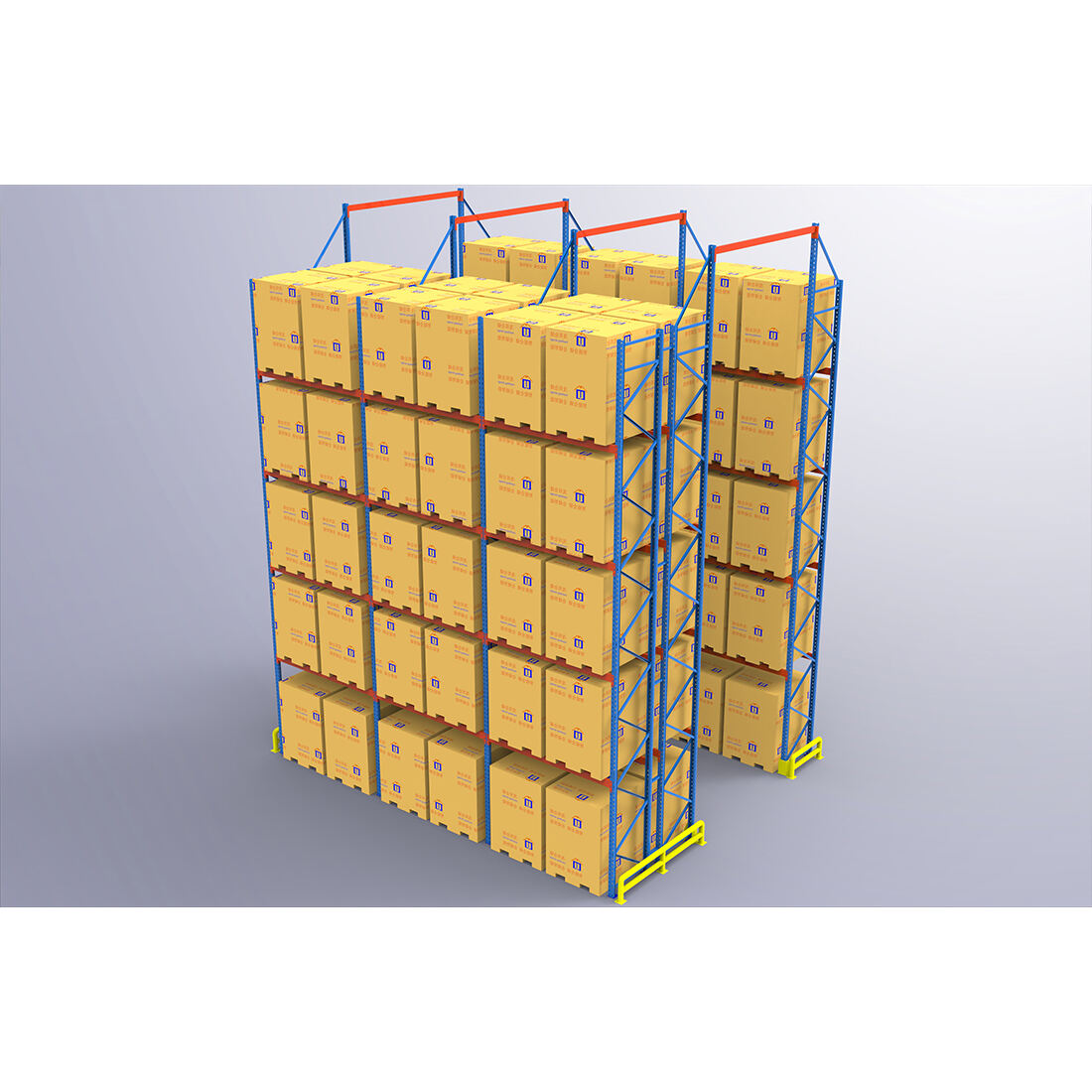

High Space Utilization: These units facilitate high-level storage, with individual upright columns reaching heights of up to 12 meters, effectively increasing warehouse storage height. They enhance the vertical space utilization rate by over 30% and support "narrow aisle" designs to minimize the occupation of non-storage areas.

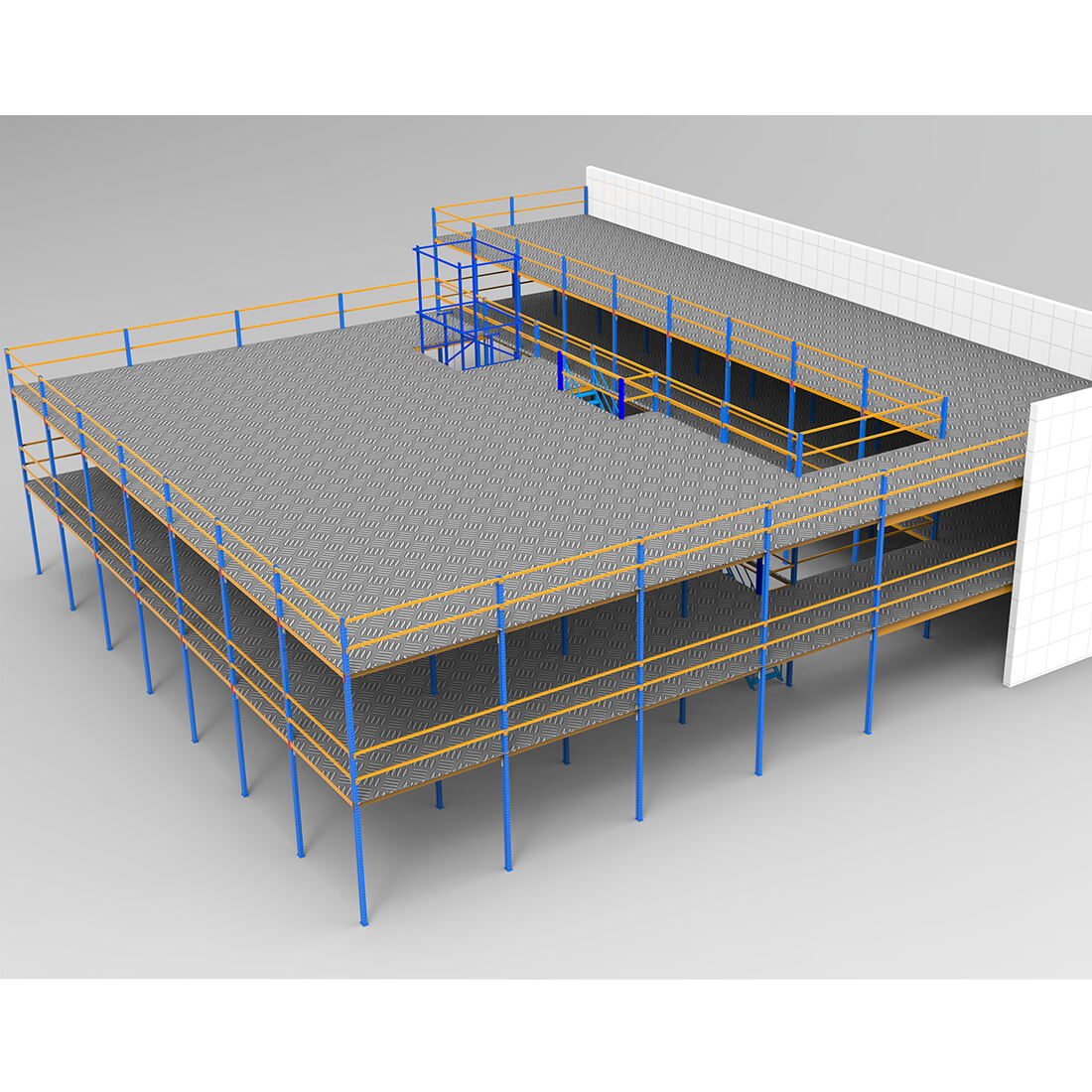

Flexible and Adjustable: Beam heights can be freely adjusted in increments of 75mm or 50mm to accommodate various goods sizes. Shelves can be swapped out to adapt to different product dimensions. Additionally, they can be expanded into mezzanine racks, automated stereoscopic warehouses, and more.

Significant Cost-Effectiveness: Featuring fewer structural components, straightforward production processes, and economical procurement costs, installation is simplified and can be performed by ordinary workers following basic training, with minimal subsequent maintenance expenses.

Safe and Reliable: Beams and upright columns are secured with clips or bolts, offering earthquake resistance and anti-tilting stability. Standard features include non-slip shelves and safety guardrails, and they can be equipped with column foot guards and anti-collision bars to ensure the protection of goods and personnel.

Application scenario

Beam-type shelves are applicable in various industries, such as the storage of heavy materials like automotive parts and machinery in the manufacturing sector, standardized pallet storage of food and beverage, and daily care products in the fast-moving consumer goods industry. They are also used in e-commerce logistics for sorting centers with a wide variety of SKUs and high turnover rates, as well as in third-party warehousing for customizing flexible storage solutions for different clients.

、

、

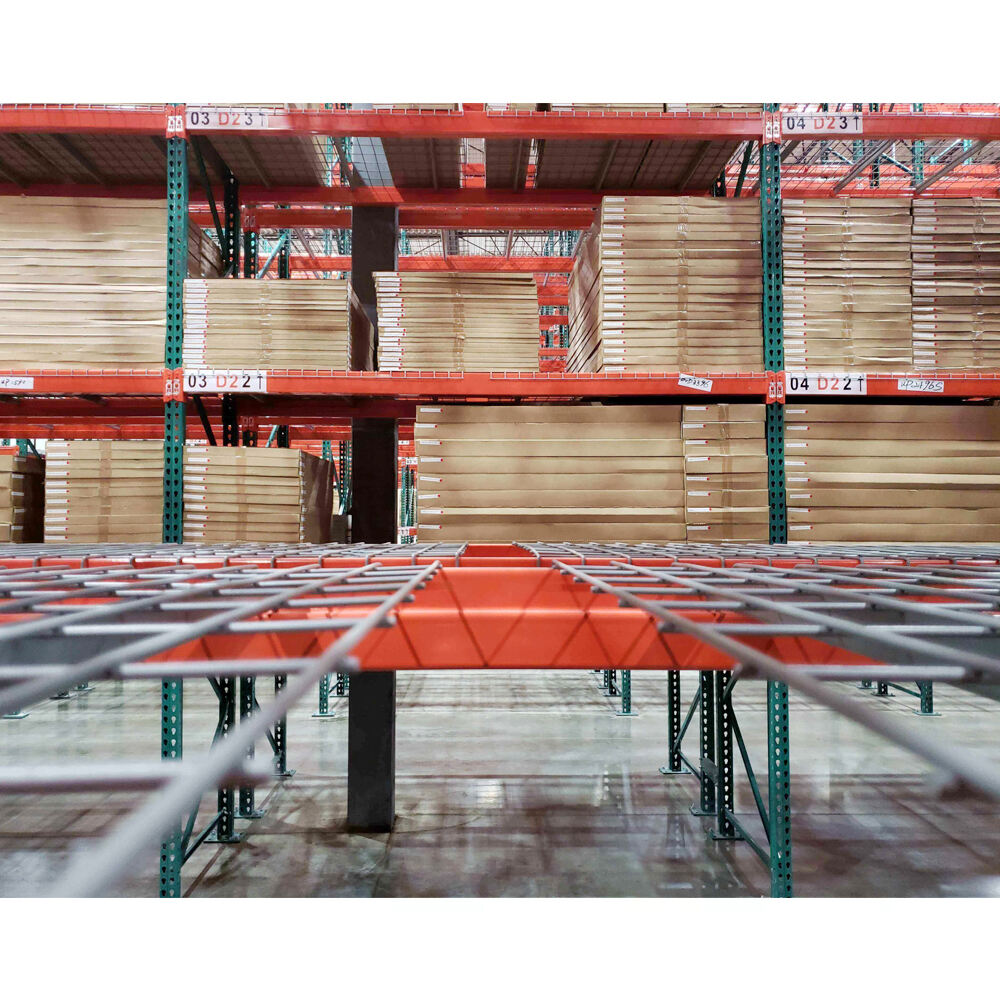

Real case

In large logistics warehouses, beam-type shelves are commonly used to store a large amount of goods. For example, an e-commerce logistics center uses beam-type shelves. According to the different sizes and weights of the goods, the height of the beams is flexibly adjusted, combined with forklift operations, to achieve rapid access to goods, significantly improving storage efficiency, while fully utilizing the vertical space of the warehouse and enhancing space utilization.

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

TH

TH

MS

MS

HMN

HMN

KM

KM

LO

LO

MR

MR

TA

TA

MY

MY

SD

SD