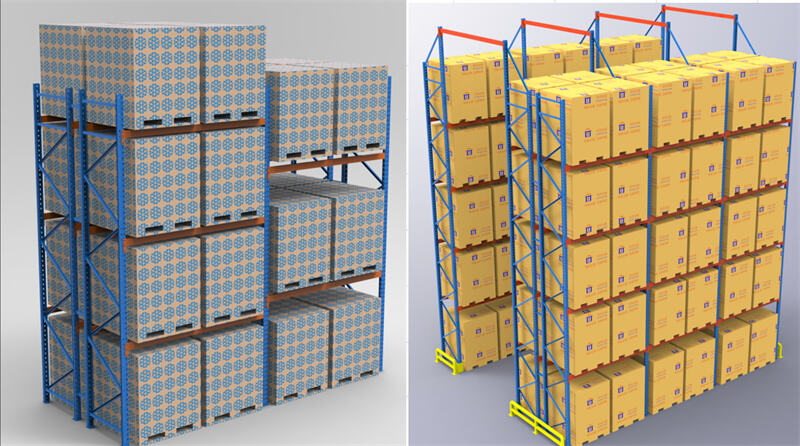

Quali sono le differenze tra scaffali a doppia profondità e scaffali pesanti ordinari?

Gli scaffali sono un tipo di struttura a rack utilizzata per immagazzinare merci e possono offrire varie combinazioni in base alle esigenze specifiche degli utenti. Tra scaffali heavy-duty ordinari e scaffali a doppia profondità, quale dei due è migliore?

Gli scaffali heavy-duty, spesso indicati dai professionisti del settore come scaffali a travi, sono assemblati con precisione utilizzando colonne, travi, controventi orizzontali, diagonali e bulloni autobloccanti. Prevengono in modo efficace problemi di stabilità negli scaffali causati da bulloni allentati.

Le sue caratteristiche principali sono:

1. Le merci vengono generalmente caricate completamente utilizzando attrezzature per il caricamento a unità, come pallet e gabbie per lo stoccaggio, e successivamente vengono riposte sugli scaffali per essere conservate in sicurezza.

2. Questo tipo di scaffale è il più comune e ampiamente utilizzato tra le varie tipologie ed è adatto alla maggior parte degli ambienti di magazzino e a diversi tipi di merci.

3. La macchina per movimentazione può raggiungere qualsiasi posizione di stoccaggio per effettuare operazioni di deposito e prelievo, raggiungendo una selettività del 100% e garantendo operazioni semplici e rapide.

4. Grazie alle operazioni meccaniche di stoccaggio, non solo si migliora l'efficienza lavorativa e si riduce il tempo di operazione, ma si diminuisce anche l'intensità del lavoro per i dipendenti.

5. La luce unitaria può essere progettata entro 4 metri, la profondità entro 1,5 metri e l'altezza degli scaffali a livello basso e alto può essere controllata entro 12 metri.

6. L'altezza di ogni livello può essere regolata liberamente a multipli interi di 75 millimetri, per soddisfare le esigenze di spazio di merci di dimensioni diverse.

Gli scaffali a doppia profondità, noti anche come scaffali a doppio fondo, rappresentano una soluzione di stoccaggio densa sviluppata a partire dagli scaffali tradizionali a travi. Questo tipo di scaffalatura adotta una struttura progettuale a doppia fila parallela ed è utilizzato in abbinamento a carrelli elevatori a forbice per consentire processi operativi efficienti. Il tasso di utilizzo dello spazio del magazzino è pari al 42% circa e la selettività raggiunge il 50%. La larghezza del corridoio viene personalizzata in base alle dimensioni del carrello elevatore e la sua struttura è simile a quella dello scaffale regolabile. Gli scaffali a doppio fondo sono stati ampiamente applicati in numerosi settori, tra cui alimentare, bevande, tabacco, industria cartaria e produzione, grazie ai vantaggi rappresentati dall'elevata utilizzazione dello spazio e alla grande capacità di immagazzinamento.

Le sue caratteristiche principali sono:

1. Il design dei traversi è relativamente basso, favorendo l'operatività; l'altezza operativa può raggiungere gli 8 metri.

2. Moderata liquidità delle scorte, con una flessibilità pari al 50%.

3. Adatto per ambienti di magazzino con frequenza ridotta di prelievo, con un'efficienza nell'utilizzo del suolo fino al 42%.

4. Rispetto agli scaffali tradizionali a travi incrociate, la sua capacità di stoccaggio può essere raddoppiata.

5. È necessario prevedere circa 3,3 metri di spazio per i corridoi delle carrelli elevatori.

6. Adotta una avanzata strategia di accesso last-in-first-out, rendendo difficile attuare il principio first-in-first-out.

7. Tra tutti i sistemi di magazzino verticale, il costo di costruzione per posizione su scaffale è il più basso, rendendolo uno dei sistemi di scaffalature più economici.

Quindi, quale dei due è più adatto: gli scaffali pesanti ordinari o gli scaffali a doppia profondità?

In realtà, entrambi presentano vantaggi specifici. La percentuale di prelievo degli scaffali pesanti ordinari può raggiungere il 100%, ed è comodo implementare il principio di stoccaggio first-in-first-out. Gli scaffali a doppia profondità invece offrono migliori prestazioni in termini di utilizzo dello spazio, con una percentuale di prelievo di circa il 50%, ed è più difficoltoso attuare il principio first-in-first-out.

Quindi, come possono gli utenti effettuare scelte intelligenti?

Quando si sceglie uno scaffale, gli utenti devono innanzitutto chiarire le proprie caratteristiche e le esigenze specifiche. Solo in questo modo potranno selezionare il tipo di scaffale più adatto alle proprie necessità. Naturalmente, qualora gli utenti incontrassero difficoltà nel definire autonomamente le proprie esigenze, noi, da una prospettiva professionale, valuteremo complessivamente le caratteristiche e i bisogni dell'utente, aiutandolo a scegliere il tipo di scaffale più appropriato e progettando per loro una soluzione completa di archiviazione.

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

TH

TH

MS

MS

HMN

HMN

KM

KM

LO

LO

MR

MR

TA

TA

MY

MY

SD

SD