Sistem Rak Pallet Baja Selektif Tugas Berat: Meningkatkan Efisiensi Operasi Gudang Industri

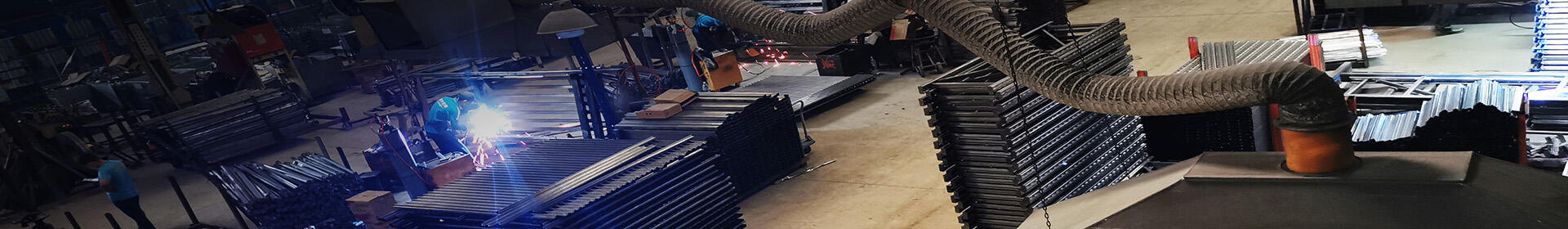

Sistem rak pallet baja selektif tugas berat merupakan peralatan utama di bidang penyimpanan industri. Dengan kinerja komprehensif yang sangat baik, sistem ini telah menjadi solusi penyimpanan pilihan bagi pabrik dan gudang besar.

Karakteristik utamanya sangat menonjol. Diproduksi secara presisi dari baja berkekuatan tinggi, struktur rak ini stabil dan andal serta memiliki kapasitas daya tahan beban yang kuat. Kapasitas beban per lapisan mencapai level ton, sehingga mampu memenuhi kebutuhan penyimpanan barang palet yang berat dengan mudah. Pada saat yang sama, rak ini memiliki tingkat fleksibilitas penyesuaian yang tinggi. Jarak antar lapisan dapat disesuaikan secara bebas sesuai ketinggian dan berat barang, serta kompatibel sempurna dengan bahan baku dan produk jadi dalam berbagai spesifikasi, sehingga secara signifikan meningkatkan tingkat pemanfaatan ruang pergudangan.

Keunggulan utama sistem ini berpusat pada integrasi ganda antara efisiensi dan kepraktisan.

Pertama, menawarkan akses yang efisien dan nyaman. Dengan desain akses selektif, setiap lokasi kargo dapat secara independen menangani masuk dan keluarnya barang tanpa perlu memindahkan barang di sekitarnya. Ketika digunakan bersama forklift, sistem ini memungkinkan operasi akses cepat, secara signifikan meningkatkan efisiensi perputaran gudang. Fitur ini sangat cocok untuk skenario manajemen barang dengan berbagai macam jenis dan jumlah kecil.

Kedua, tahan lama dan mudah dirawat. Material baja memiliki ketahanan korosi dan deformasi yang sangat baik, masa pakai panjang, serta biaya perawatan harian yang rendah. Sistem ini dapat beradaptasi secara stabil terhadap lingkungan penyimpanan yang kompleks di gudang, seperti lingkungan dengan kelembapan tinggi dan debu.

Ketiga, hal ini memungkinkan perakitan dan perencanaan yang fleksibel. Dengan desain perakitan modular, kombinasi bentuk dapat direncanakan secara fleksibel sesuai tata letak gudang yang sebenarnya, sehingga memaksimalkan nilai ruang vertikal maupun horizontal. Hal ini secara efektif mengatasi permasalahan umum di industri mengenai pemborosan ruang dalam gudang besar.

Dalam hal skenario aplikasi, sistem ini memiliki jangkauan luas dan secara tepat memenuhi kebutuhan berbagai industri. Sistem ini terutama diterapkan di gudang pabrik manufaktur untuk penyimpanan terpusat suku cadang berat, bahan baku, dan produk jadi. Di samping itu, sistem ini cocok digunakan di pusat distribusi logistik berskala besar, gudang rantai dingin, dan sebagainya, yang menangani tugas utama pemindahan barang dan penyimpanan sementara. Sistem ini juga memainkan peran penting dalam industri barang berat seperti bahan bangunan dan mesin, serta basis pergudangan e-niaga besar, membantu perusahaan mewujudkan manajemen pergudangan terstandar dan meningkatkan efisiensi rantai pasok.

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

VI

VI

TH

TH

MS

MS

HMN

HMN

KM

KM

LO

LO

MR

MR

TA

TA

MY

MY

SD

SD