Highly efficient, this tool is very important when it comes to optimizing the use of space in a warehouse. It is a perfect solution for storing items and keeping them in order. Selective racks are user-friendly, easy to install and the most popular choice amongst businesses. We will take you into those multiple beneficial aspects of selective rack systems.

Selective rack is good for easy access to products This efficiency allows workers to access inventory quickly and fulfill stock, which then saves time for more efficient productivity. In addition, its flexibility in handling items of different sizes is what makes selective rack suitable for mixed and varied storage applications.

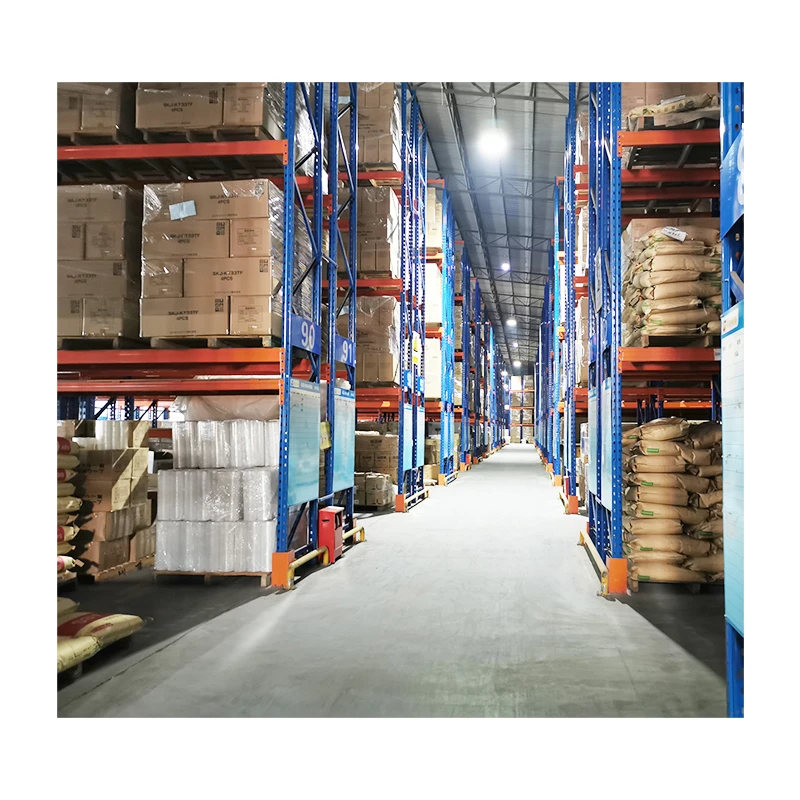

If we talk about warehouse management, space optimisation is the key thing here. When used properly, selective rack system provides strategic utilization of vertical storage space. The system makes full use of warehouse space by using levels for product storage without impacting the valuable floor area.

A second major benefit of using selective rack systems is overhead, which means creating narrow aisles. This allows more racks to be located in tight space without blocking the movement of workers and material.

Primary considerations in Choosing the Right Selective Rack System or Product

There exist a number of vital considerations regarding the implementation and practice of selective rack system adoption. The size and weight of the products needed to be stored hold significant importance as it helps in determining what rack measurements would suit them best, how much they can support? The racks must be strong enough to hold the items that would need to store hence this is something also has his utmost importance.

Furthermore, the design of warehouses must be thoroughly studied in order to facilitate proper installation of a racking system. The design must facilitate mobility so that personnel and merchandise can make their way around without any hassle. Type of equipment used for product transport (forklift, pallet jack)

There are several designs of selective rack systems that you can choose from depending on your warehousing requirements. One of the most common styles is a user-friendly teardrop design which makes it easy to set these up and adjust them down with its bolt/nut slots. Or, for higher volume storage needs and many more drain holes with a greater strength to weight ratio: structural or bolted designs.

Selective rack systems are usually assembled and fixed securely in place during the installation process. Since they must be installed correctly and safely, following the manufacturer's guidelines is very important.

Using selective rack technology can transform the way an organisation manages picking and replenishment within a warehouse. This technology helps workers get products faster, making it quicker to retrieve items and put them back which in turn increases efficiency and productivity.

In addition, selective rack technology can even enhance these operations with automated systems. These high-end systems will save you much of the time and effort to move products off/from racks manually. This can save time as well reducing the chance of people getting tools hurt.

To recap, the integration of selective rack systems provide several advantages to warehouse functions including better space utilization and efficient organization. Selective rack makes a strong case as the top choice for many warehouses because it is easy to use and can accommodate products of all shapes and size. The proper selection of a selective rack system is part science, with some key elements being product sizes, warehouse dimensions and equipment compatibility. Installation Installation following manufacturer's guidelines is critical to guarantee that RAPS systems operate securely and properly. In the end integration of selective racking technology means more efficiency and productivity in any warehouse.

shelf made steel products first look control production supply selective rack timely custom storage rack specific requirement warehouse after-sales service customized issues occur ensuring completely secure

At Guangzhou Maobang Storage Equipment Co. LTD., we are selective rack with more than 25 years of expertise. We offer a range of storage solutions that are high-quality and meet various industrial needs. Our product range includes Supermarket Shelves and Wire Mesh Storage Cages and a Steel Pallet. Our products are constructed using only the finest materials to ensure durability and a long life.

selective rack layouts that work and provide adequate storage capacity can help you maximize profits, satisfy high demand periods and ensure the success of your operation. Warehouse pallet racking systems allow you to increase vertical space and enhance storage efficiency. We're here for customers who need to maximize their space. We will help you increase your storage efficiency by optimizing vertical space. We are the leading rack manufacturer in the market and we have all the production equipment and the knowledge to assist you with the storage objectives you have set.

At Maobang, we are dedicated to providing reliable and efficient storage solutions that maximize the utilization of space and selective rack. We have custom-designed racks available for our customers and provide high-quality after-sales service and technical support to ensure that our products feature the most cutting-edge design concepts and the most modern manufacturing techniques.We're sure that we can offer the most efficient storage solutions within the industry. Through close collaboration with our clients and suppliers, we're committed to establishing a mutually beneficial partnership. Maobang will help you achieve your storage requirements by offering all of your racking requirements.